What is a Rental LED Display Screen?

In today's visually driven world, the demand for high-quality, dynamic display solutions have never been greater. One technology that has emerged as a game-changer is the rental LED display screen. These versatile and powerful tools are transforming the way events, presentations, and performances are experienced, offering a unique blend of flexibility, visual impact, and cost-effectiveness.

What is a Rental LED Display Screen? A rental LED display screen is a modular, high-resolution display system designed specifically for temporary use. Unlike traditional permanent displays, these screens are built to be easily assembled, disassembled, and transported, making them ideal for a wide range of events and venues. They are constructed from lightweight yet durable materials, ensuring they can withstand the rigors of frequent setup and teardown.

The core of these screens is the LED module, which consists of numerous light-emitting diodes arranged in a matrix pattern. These modules are connected to form larger displays, and the resolution of the screen is determined by the pixel pitch—the distance between each LED. A smaller pixel pitch means higher resolution, allowing for clearer and more detailed images, even at close range.

Key Features and Advantages

Flexibility

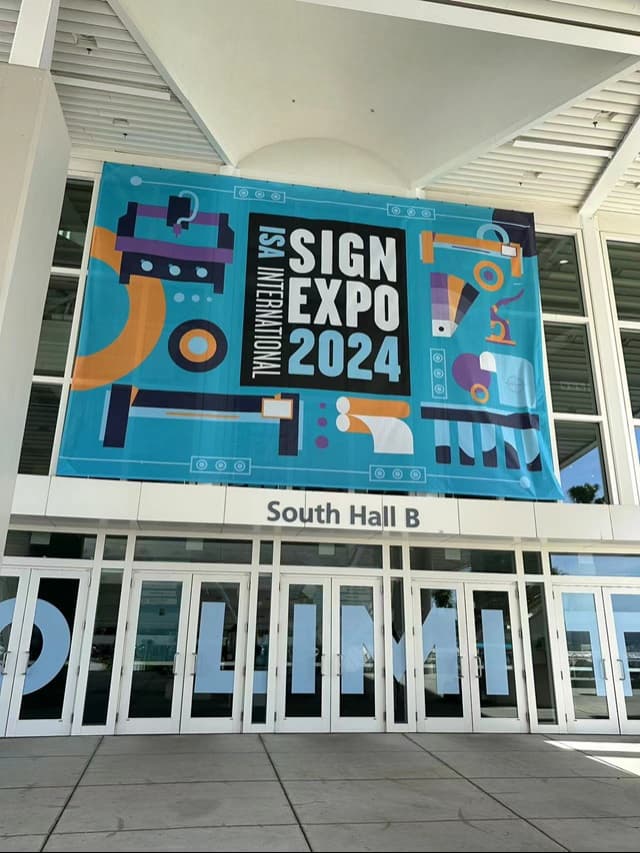

One of the most significant advantages of rental LED display screens is their adaptability. They can be customized to fit almost any space or event layout, whether it's a straight, curved, or uniquely shaped display. This flexibility makes them perfect for concerts, corporate events, sports arenas, and outdoor festivals.

High Visual Impact

LED screens are renowned for their high brightness and excellent color reproduction, making them visible even in bright daylight or under intense stage lighting. This high visual quality ensures that content is engaging and captivating, whether it's live video feeds, animations, or promotional messages.

Cost-Effective

For many event organizers, purchasing a permanent LED display is not feasible due to the high upfront costs. Rental screens offer a more budget-friendly solution, allowing users to access state-of-the-art display technology without a large investment. Rental fees are typically based on the duration of use and the size of the screen, making them a flexible option for any budget.

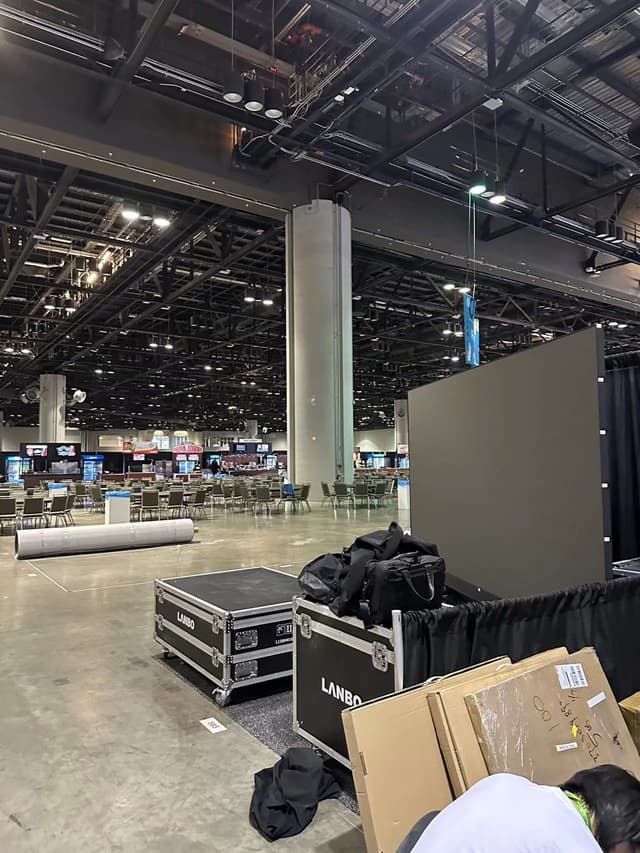

Easy Setup and Transportation

The modular design of rental LED screens allows for quick assembly and disassembly by trained technicians, saving time and effort. The lightweight materials also make them easier to transport, reducing logistical challenges and costs. Many rental companies even offer comprehensive setup and teardown services, ensuring a seamless experience for event planners.

Applications and Future Prospects

Rental LED display screens are used in a wide variety of applications, from live concerts and corporate events to sports arenas and outdoor festivals. They are also increasingly popular for weddings, product launches, and special occasions, where they can create unique and personalized visual backdrops.

As technology continues to advance, rental LED screens are becoming even more sophisticated. Higher resolutions, improved color accuracy, and increased brightness are enhancing the visual quality of these screens. Innovations in screen design and materials are also making them lighter, more durable, and easier to transport.

In summary, rental LED display screens are a versatile, high-impact, and cost-effective solution for temporary display needs. Their modular design, visual quality, and ease of use make them an essential tool for creating memorable and engaging events. Whether for live performances, corporate presentations, or special occasions, rental LED screens are transforming the way we experience visual content, making them a must-have technology for the modern event industry.