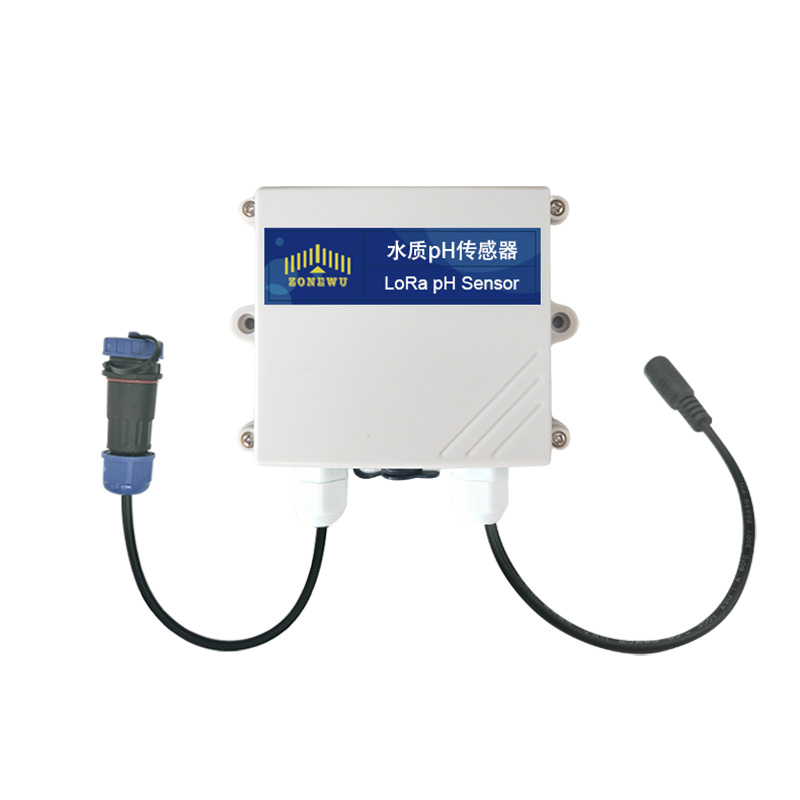

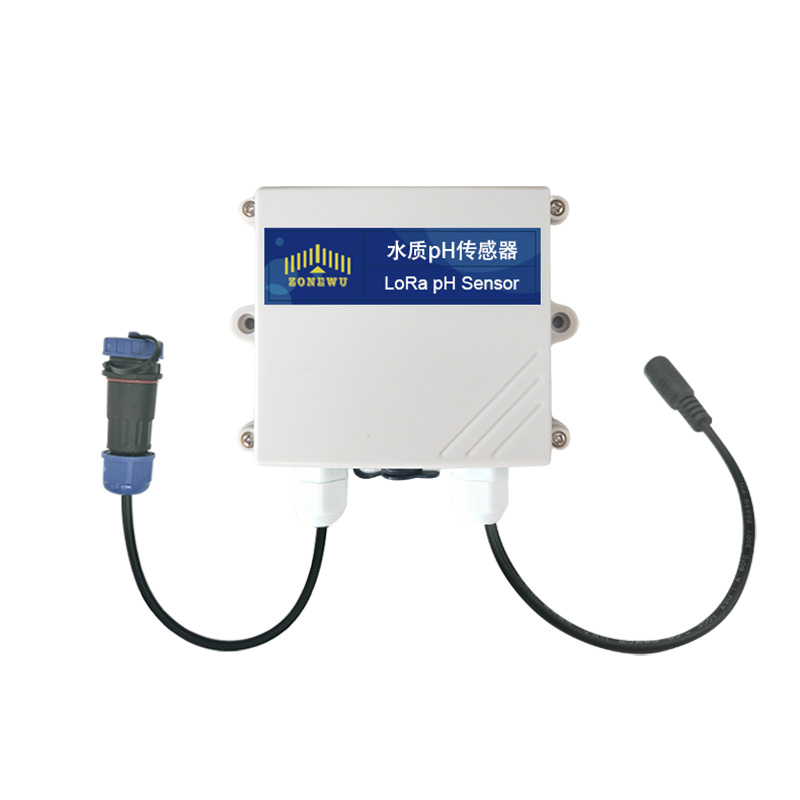

With the rapid development of the Internet of Things (IoT) technology, LoRaWAN, as a low-power wide-area network (LPWAN) communication technology, has found widespread application in the field of environmental monitoring. Water quality PH sensors, as an important part of environmental monitoring, enable remote, real-time, and low-cost water quality monitoring through the LoRaWAN network, providing strong technical support for environmental protection and water resource management. This article will focus on introducing ZONEWU's LoRaWAN water quality PH sensor.

Application Background

The PH value of water quality is a crucial indicator for measuring the acidity or alkalinity of water bodies, which is of great significance for agricultural irrigation, industrial water use, aquaculture, and drinking water safety. Traditional water quality monitoring methods require manual sampling and laboratory analysis, which is not only time-consuming and labor-intensive but also unable to achieve continuous monitoring. The emergence of LoRaWAN water quality PH sensors has effectively addressed this issue.

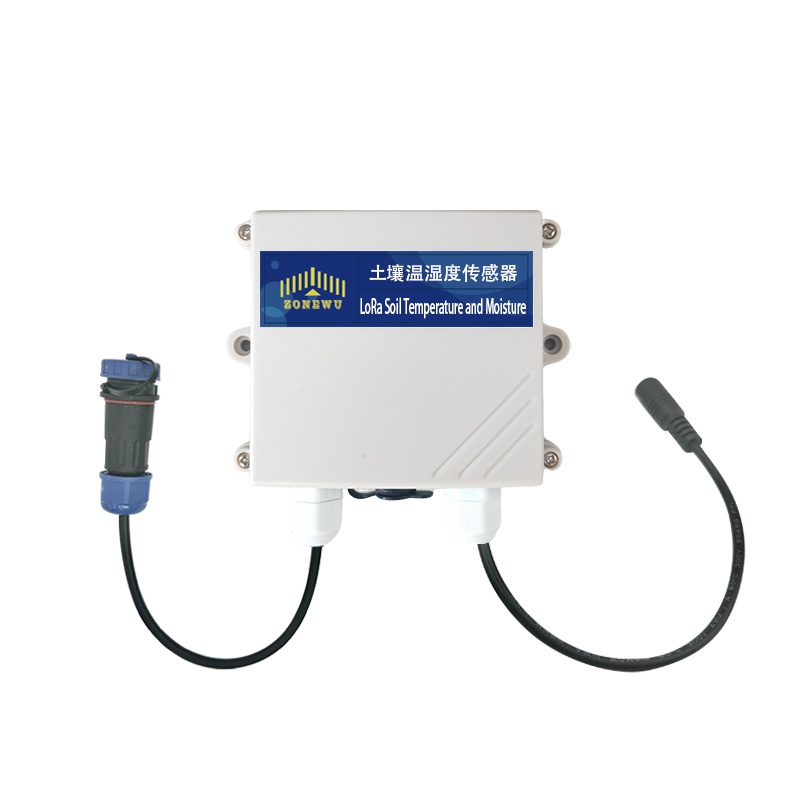

Introduction to ZONEWU LoRaWAN Water Quality PH Sensor

As a leading enterprise in the IoT field, ZONEWU's LoRaWAN water quality PH sensor enjoys high recognition and popularity in the market. In addition to possessing basic functions such as high-precision measurement, LoRaWAN communication technology, real-time data transmission, long-term stable operation, waterproof and moisture-proof design, and easy installation and maintenance, this sensor also offers the following unique advantages:

1. High-Precision Measurement and Automatic Calibration

ZONEWU's LoRaWAN water quality PH sensor adopts advanced PH electrodes and automatic calibration technology to accurately measure the acidity or alkalinity of water bodies with minimal error. The sensor integrates an automatic calibration function that automatically adjusts measurement parameters based on environmental changes to ensure the accuracy of measurement results.

2. Remote Monitoring and Management

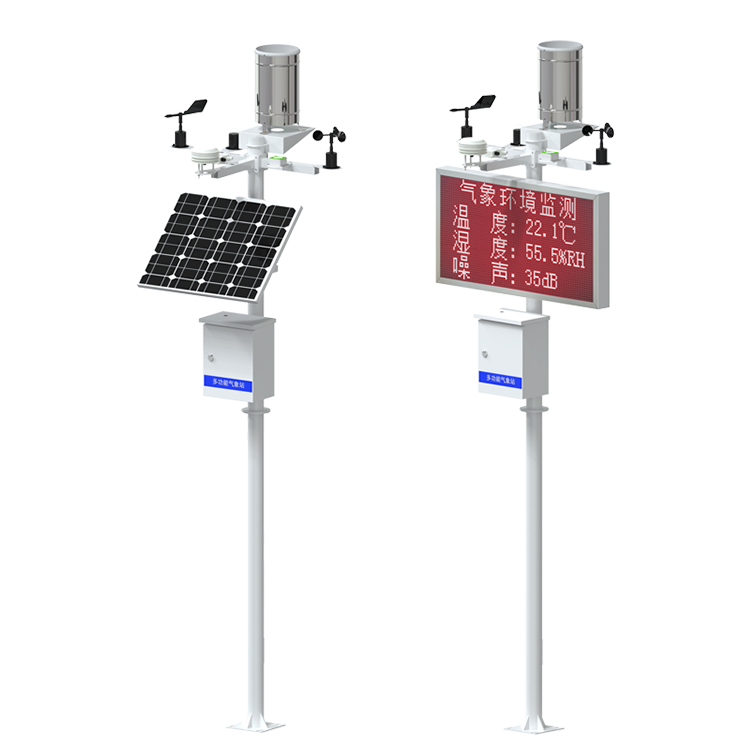

Users can remotely monitor the operating status and data changes of the sensor through the LoRaWAN network. ZONEWU provides a cloud management platform that supports data visualization, historical data inquiry, alarm settings, and other functions, enabling users to grasp water quality conditions at any time and take timely measures.

3. Low-Power Design

The sensor adopts a low-power circuit design and配合the low data transmission frequency of LoRaWAN technology, enabling the sensor to operate stably for an extended period without battery replacement. This significantly reduces maintenance costs and enhances the practicality of the sensor.

4. Waterproof, Moisture-Proof, and Corrosion-Resistant

For outdoor and underwater environments, ZONEWU's LoRaWAN water quality PH sensor offers excellent waterproof and moisture-proof performance as well as corrosion resistance. The sensor's housing is made of high-strength, corrosion-resistant materials to ensure that the device can operate normally in harsh environments.

Functional Introduction

1. Real-Time Monitoring

The sensor can monitor water quality PH values in real-time and transmit data to the cloud server via the LoRaWAN network. Users can view data in real-time through PCs or mobile devices to stay informed about water quality conditions.

2. Historical Data Inquiry

ZONEWU's cloud management platform supports historical data inquiry functionality. Users can view trends in water quality PH values over a past period, providing data support for water quality management.

3. Alarm Settings

Users can set alarm thresholds on the cloud management platform. When the water quality PH value exceeds the set threshold, the system will automatically trigger an alarm to remind users to take timely measures.

Application Areas

1. Agricultural Irrigation

In the field of agricultural irrigation, ZONEWU's LoRaWAN water quality PH sensor can monitor the acidity or alkalinity of irrigation water, guiding farmers to apply fertilizers reasonably, thereby improving crop yield and quality.

2. Industrial Water Use

During industrial production processes, there are strict requirements for the acidity or alkalinity of water. The sensor can monitor the PH value of industrial water in real-time to ensure production safety and product quality.

3. Aquaculture

In aquaculture, the PH value of water quality is crucial for the growth of fish and other aquatic organisms. Through real-time monitoring, water quality can be adjusted in a timely manner to provide a good growth environment for aquatic organisms.

4. Drinking Water Safety

The PH value of drinking water directly affects people's health. The sensor can be deployed in water treatment plants or water supply networks to monitor water quality in real-time and ensure drinking water safety.

ZONEWU's LoRaWAN water quality PH sensor, with its unique advantages such as high-precision measurement, remote monitoring and management, low-power design, and waterproof, moisture-proof, and corrosion-resistant properties, demonstrates huge application potential in the field of water quality monitoring. Through real-time, remote, and low-cost monitoring, it provides new solutions for water resource management, contributing to the sustainable utilization of water resources and environmental protection. With continuous technological advancements and expanding applications, ZONEWU's LoRaWAN water quality PH sensor will play an increasingly important role in the future.