Application of Gas Adsorption Techniques in Characterizing Titanium Dioxide

Abstract:

Titanium dioxide, widely known as titanium white, is an important white inorganic pigment extensively used in various industries such as coatings, plastics, rubber, papermaking, inks, and fibers. Studies have shown that the physical and chemical properties of titanium dioxide, such as photocatalytic performance, hiding power, and dispersibility, are closely related to its specific surface area and pore structure.

Using static gas adsorption techniques for precise characterization of parameters like specific surface area and pore size distribution of titanium dioxide can be employed to evaluate its quality and optimize its performance in specific applications, thereby further enhancing its effectiveness in various fields.

About Titanium Dioxide:

Titanium dioxide is a vital white inorganic pigment primarily composed of titanium dioxide. Parameters such as color, particle size, specific surface area, dispersibility, and weather resistance determine the performance of titanium dioxide in different applications, with specific surface area being one of the key parameters. Specific surface area and pore size characterization help understand the dispersibility of titanium dioxide, thereby optimizing its performance in applications such as coatings and plastics. Titanium dioxide with a high specific surface area typically exhibits stronger hiding power and tinting strength.

In addition, research has indicated that when titanium dioxide is used as catalyst support, a larger pore size can enhance the dispersion of active components and improve the overall catalytic activity, while a smaller pore size increases the density of active sites, aiding in improving reaction efficiency. Hence, by regulating the pore structure of titanium dioxide, its performance as a catalyst support can be improved.

In summary, the characterization of specific surface area and pore size distribution not only aids in evaluating and optimizing the performance of titanium dioxide in various applications but also serves as an important means of quality control in the production process. Precise characterization of titanium dioxide enables a better understanding and utilization of its unique properties to meet the requirements in different application fields.

Application Examples of Gas Adsorption Techniques in Titanium Dioxide Characterization:

1. Characterization of Specific Surface Area and Pore Size Distribution of Titanium Dioxide for DeNOx Catalysts

Selective catalytic reduction (SCR) is one of the commonly applied and researched flue gas denitrification technologies. Catalysts play a crucial role in SCR technology, as their performance directly affects the efficiency of nitrogen oxide removal. Titanium dioxide serves as the carrier material for DeNOx catalysts, primarily providing mechanical support and erosion resistance to active components and catalytic additives, along with increasing the reaction surface area and providing suitable pore structures.

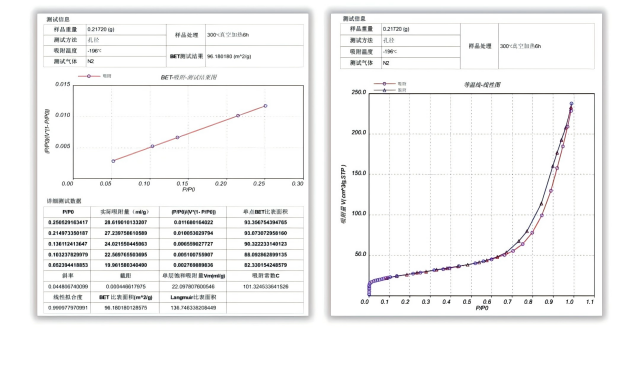

Here is an example of the characterization of titanium dioxide used as a carrier material for DeNOx catalysts using the CIQTEK V-3220&3210 series BET Surface Area & Porosimetry Analyzer. As shown in Figure 1 (Left), the specific surface area of the titanium dioxide used in the DeNOx catalyst is 96.18 m2/g, indicating a larger surface area that provides more active sites as a carrier material, thus enhancing the efficiency of the DeNOx catalytic reactions. The N2 adsorption-desorption isotherm (Figure 1, right) reveals the predominant presence of a type IV isotherm.

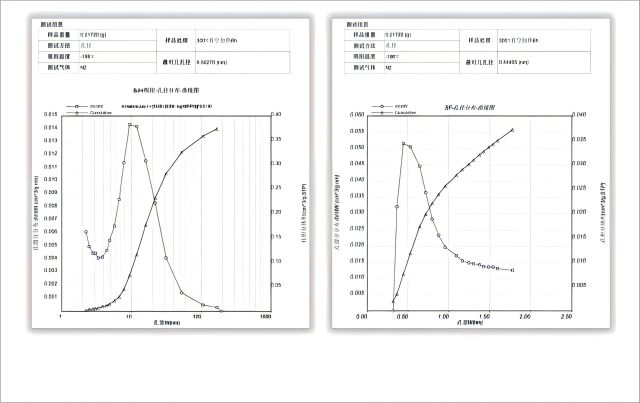

Utilizing the BJH model for mesopore size distribution analysis (Figure 2, Left), a concentrated mesopore distribution at 9.50 nm is observed. The SF pore size distribution plot (Figure 2, Right) shows the most probable micropore width of the sample to be 0.44 nm. Studying the effect of specific surface area and pore size distribution on DeNOx catalysts allows the optimization of catalyst design and DeNOx processes, improving nitrogen oxides' removal efficiency.

Figure 1. Specific surface area test results (Left) and

N2 adsorption-desorption isotherm (Right) of titanium dioxide used for DeNOx catalysts.

Figure 2. BJH pore size distribution plot (Left) and

SF pore size distribution plot (Right) of titanium dioxide used for DeNOx catalysts.

2. Characterization of Specific Surface Area and Pore Size Distribution of General Titanium Dioxide

By adjusting and controlling the specific surface area and pore size distribution of titanium dioxide for different applications, the performance and effectiveness of titanium dioxide can be assessed and improved. For example, in the coatings and plastics industries, specific surface area and pore size analysis help optimize the dispersibility and light scattering ability of titanium dioxide, ensuring uniformity and durability of coatings and improving the mechanical properties and weather resistance of plastic products. Furthermore, it provides an important means of quality control in the production process to ensure product consistency.

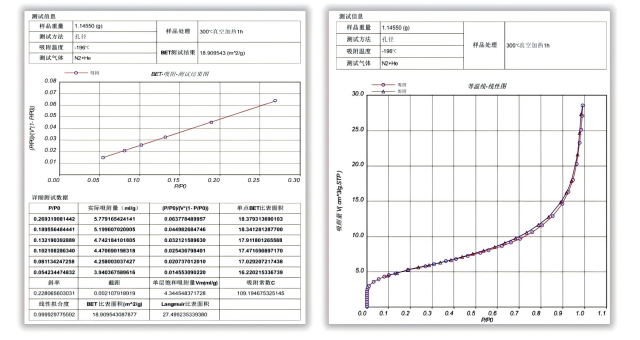

The CIQTEK V-3220&3210 series BET Surface Area & Porosimetry Analyzer is utilized for the characterization of specific surface area and pore size distribution of titanium dioxide. As shown in Figure 3 (Left), the specific surface area of the titanium dioxide sample is determined to be 18.91 m2/g using the multi-point BET equation. Further analysis of the N2 adsorption-desorption isotherm (Figure 3, Right) reveals a type II isotherm.

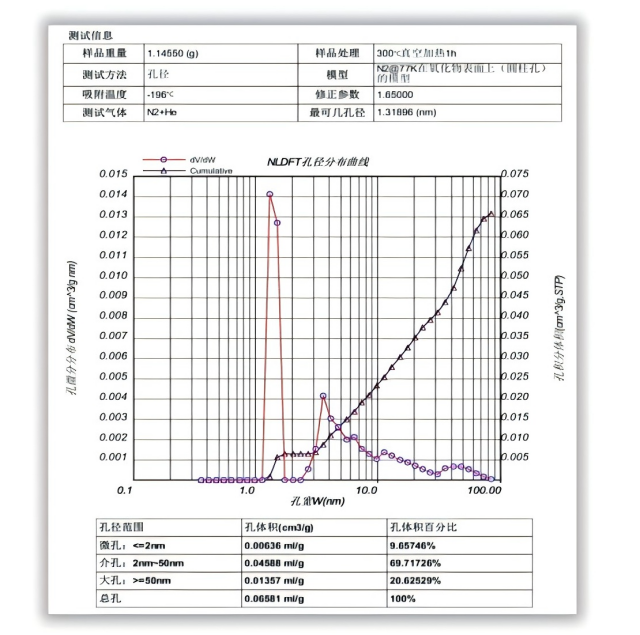

By performing NLDFT total pore size distribution analysis (Figure 4), the total pore volume of the titanium dioxide is determined to be 0.066 cm3/g, with micropores accounting for 9.66% and mesopores accounting for 69.72%. In-depth studies on the specific surface area, pore size distribution, pore volume, and their influencing factors provide valuable references for applications and performance optimization of titanium dioxide, thereby meeting the demands for high-performance titanium dioxide in different industries.

Figure 3. Specific surface area test results (Left) and N2 adsorption-desorption isotherm (Right) of a titanium dioxide sample.

Figure 4. NLDFT pore size distribution plot of a titanium dioxide sample