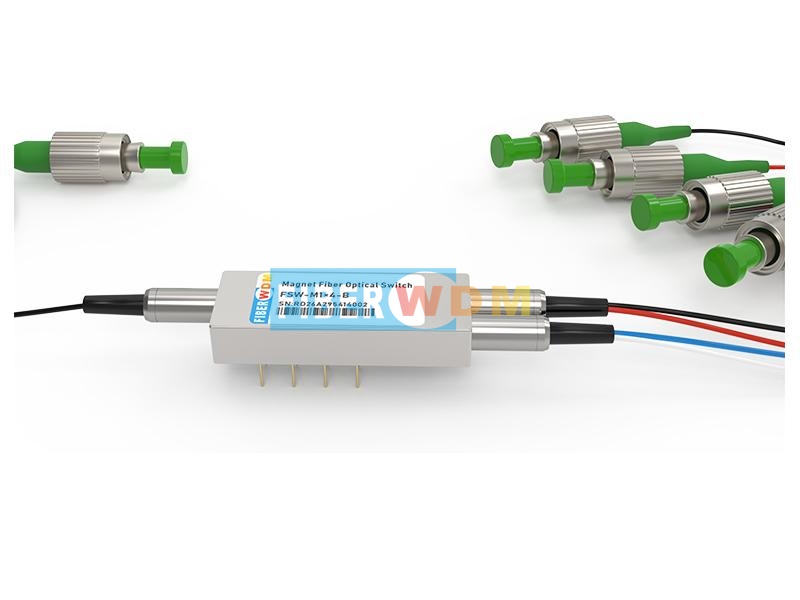

The Versatile Applications of Fiber Optic Switch Devices

Fiber optic switch devices have emerged as a cornerstone in modern communication networks, revolutionizing the way data is transmitted and managed. These devices leverage the unparalleled capabilities of fiber optics to provide high-speed, low-loss, and secure data transmission. Let's delve into the main applications of fiber optic switch devices and understand how they are shaping various industries.

1. Telecommunications and Data Centers

Fiber optic switches are indispensable in telecommunications and data centers. They enable the seamless transfer of vast amounts of data between servers, routers, and other network devices. In data centers, fiber optic switches support high-density fiber connectivity, ensuring that data flows smoothly and efficiently. This is crucial for maintaining the uptime and performance of critical applications and services.

2. Fiber-to-the-Home (FTTH) Networks

FTTH networks are becoming increasingly common, bringing high-speed internet directly to homes and businesses. Fiber optic switches play a vital role in these networks, enabling the distribution and management of optical signals. They ensure that data is transmitted with minimal loss and interference, providing users with reliable and consistent internet access.

3. Industrial Automation and Control Systems

In industrial settings, fiber optic switches are used to create robust and reliable communication networks. These networks are essential for monitoring and controlling machinery, equipment, and processes. Fiber optic switches provide the high-speed, low-latency communication required for real-time monitoring and control, ensuring the smooth operation of industrial systems.

4. Security and Surveillance Systems

Fiber optic switches are also crucial in security and surveillance systems. They enable the transmission of high-definition video and audio signals over long distances, ensuring that security personnel can monitor and respond to events in real-time. The inherent security and immunity to electromagnetic interference of fiber optics make them ideal for sensitive and critical security applications.

5. Aerospace and Defense

In the aerospace and defense industry, fiber optic switches are used in communication systems for aircraft, satellites, and other military platforms. They provide high-speed, secure communication links that are resistant to electromagnetc interference and jamming, ensuring reliable communication in harsh environments.

6. Research and Development

Fiber optic switches are also used in research and development settings, enabling scientists and engineers to conduct experiments and test new technologies. The high-speed, low-loss, and secure transmission of data make fiber optic switches ideal for research applications that require precise and reliable data collection and analysis.

In conclusion, fiber optic switch devices have a wide range of applications across various industries. From telecommunications and data centers to industrial automation, security systems, and aerospace, fiber optic switches are playing a pivotal role in shaping the future of communication networks. As technology continues to evolve, the role of fiber optic switches will undoubtedly become even more significant, enabling faster, more reliable, and secure data transmission.

FIBERWDM, as a prominent Chinese supplier and manufacturer, offers fiber optical switches with characteristics such as High Reliability, Low Latency, Scalability, Compact Design, and Durability. Our product line includes various models such as M1X1, M1X2, M1X4, M1x8, M2X2, and M2X2B, tailored to meet diverse networking needs. We pride ourselves on our customization capabilities, ensuring that our clients receive solutions that perfectly fit their specific requirements.

FiberWDM's Fiber Optic Switch support customization, if interested, please consult sales@fiberwdm.com.